So I went to Burning Man for the first time. It was strange and wonderful and difficult and beautiful, often at the same time. I…

I made a thing with TouchDesigner

TouchDesigner is a visual programming interface to make interactive video art, I guess? I’ve been doing some work with it lately, for a larger-scale project…

Let’s combine a cheap wireless doorbell with a century-old phone

We recently (ish) moved into a new place, a big old victorian in the Haight. There’s funky historical There was no doorbell for our unit,…

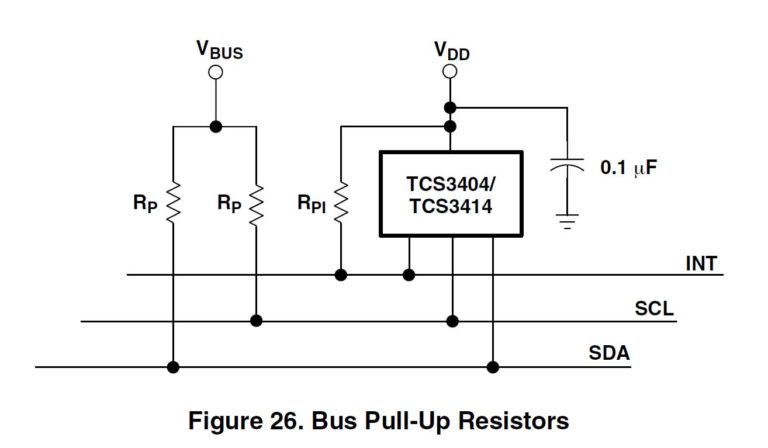

Interfacing the Arduino to the Taos TCS3414 via I2C, continued

November, so soon! I kind of had to put this one down for awhile and work on things that were not laptop-centric, I just was…

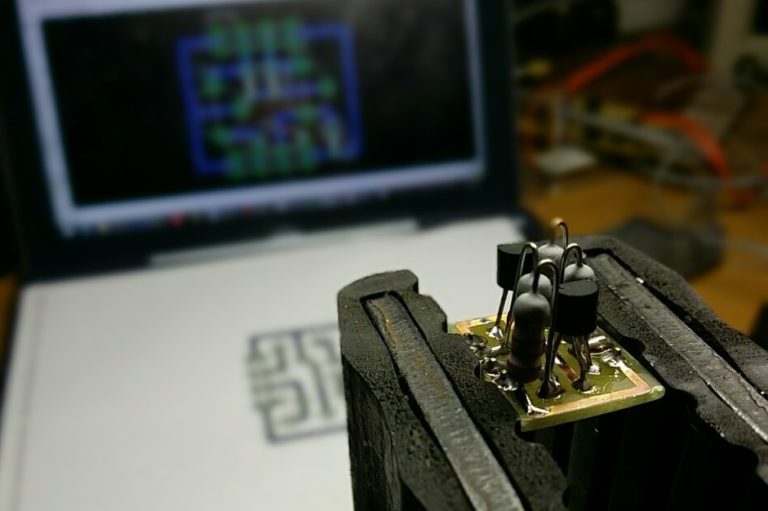

Interfacing the Arduino to the Taos TCS3414 via I2C

Well, this was a productive night: I’ve been working with the Taos TCS3414, which is a light and RGB color sensor. It’s a tiny little…

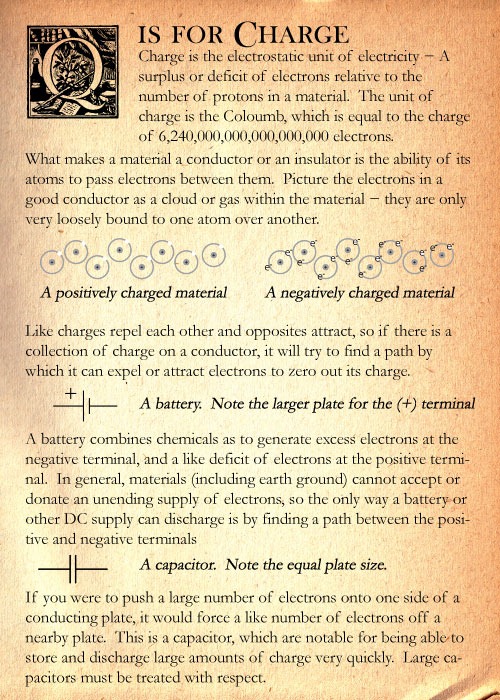

Electricity Quick Reference Cards

These are some quick reference guides I made for my dad, for Christmas. I am posting it now because June is the next month after…

My Nixie Clock Build

It’s finally done, jesus. A few years ago, I bought some electronics components from a former Eastern Bloc country. Nixie tubes are apparently still…

Rev15 of the Arduino DMX Reception Software Released

New in this version: Tested and working with IDE version 0021. I have not tested it with the new Arduino Uno hardware, but can’t think…

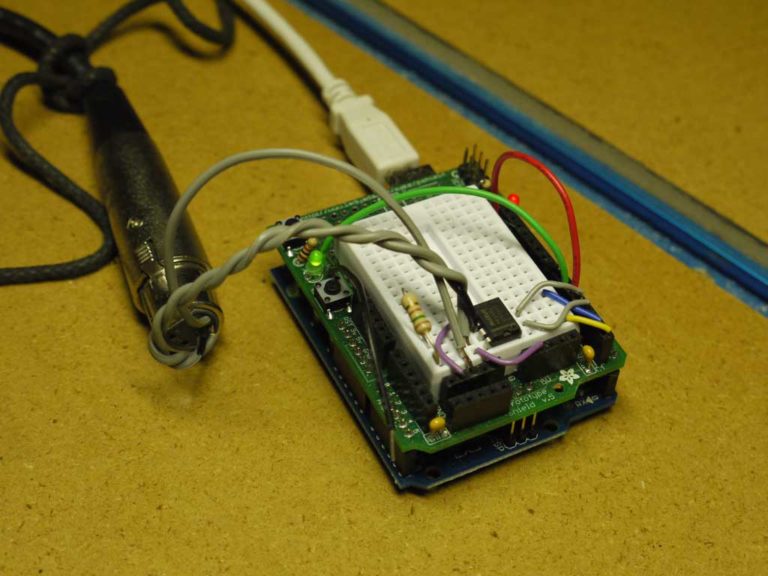

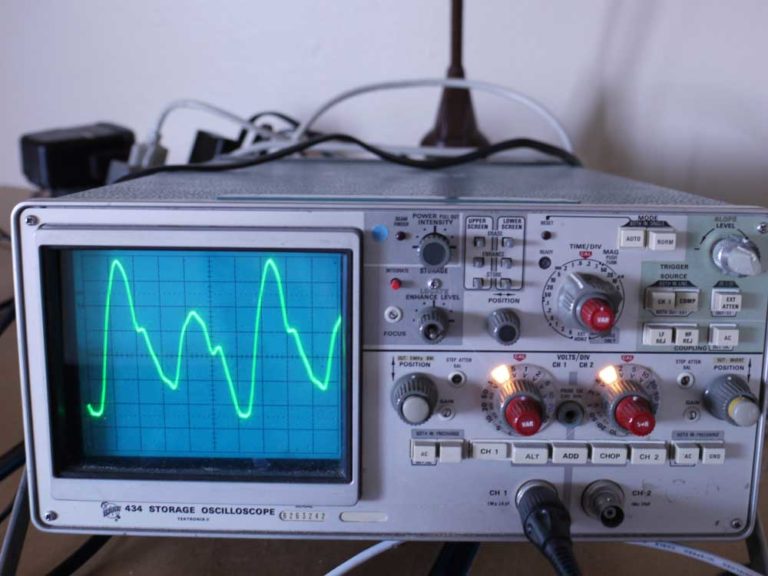

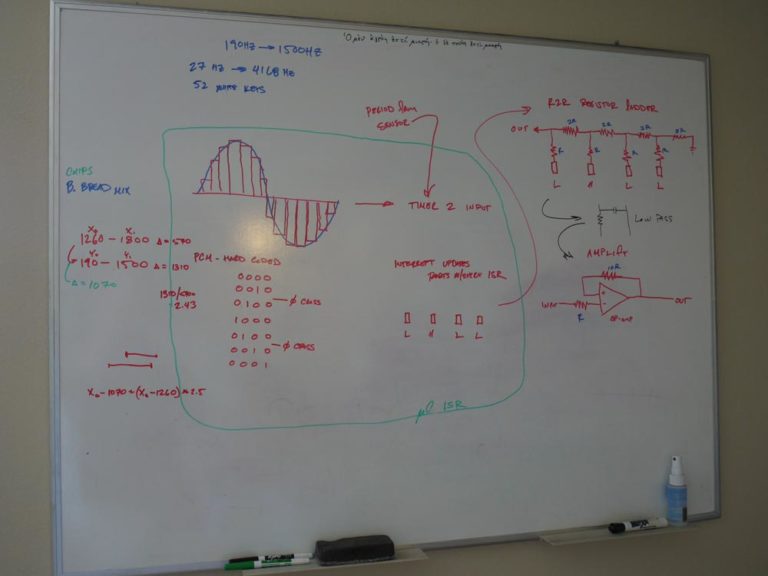

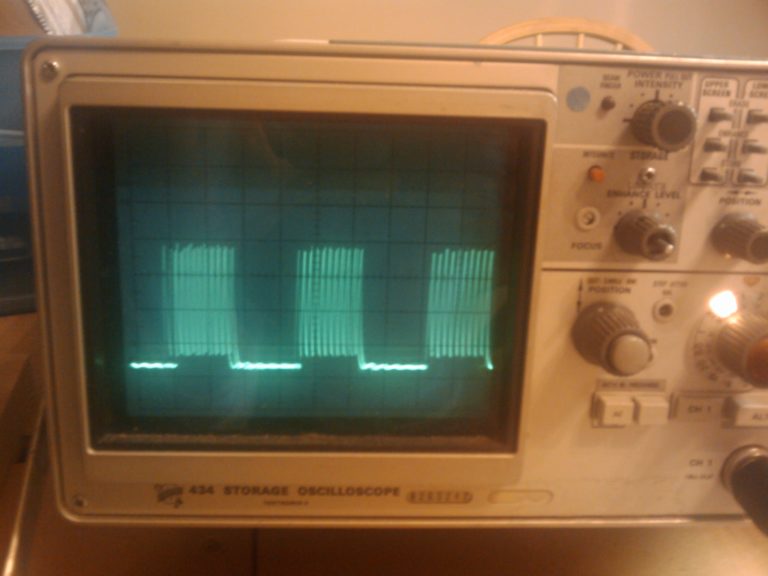

Generate Real-time Audio on the Arduino using Pulse Code Modulation

So. There are a bewildering variety of options for generating sound via the Arduino, but I’m trying to make a real-time synthesizer, with the following…

Arduino Theremin/Synthesizer Update

An Update: I’ve made considerable progress in improving the quality of the audio output. In the prior post, I was generating a square wave with…

Arduino audio output from a capacitive input

Lookee Lookee What I Did Today: So my sister is currently pursuing a PHD in music (theory) at the University of Chicago, and for her…

Rev12 of the Arduino DMX Reception Software Released

Update: This is no longer the latest version of the software. Find that here. New in this Version: In-the-field addressing via two tact switches (works…

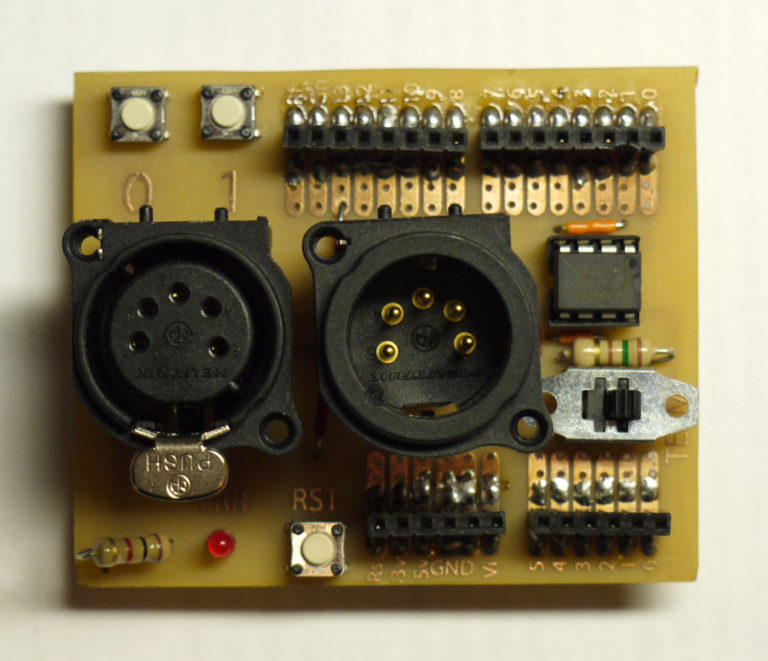

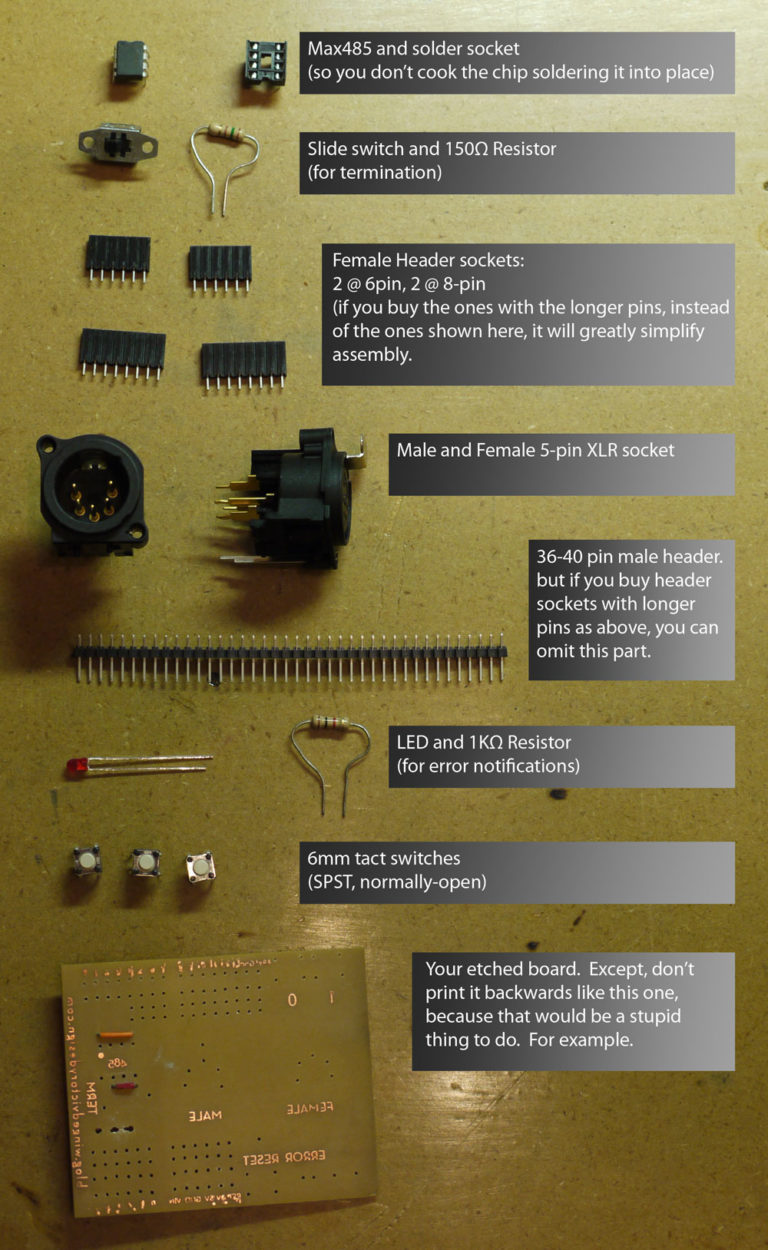

Receive DMX-512 with an Arduino

Prologue: For Christmas, I received an Arduino. If you’re not familiar with them, they’re like a little computer with a lot of pins to which…

Power Rectification Explained

I wrote this up as part of my guide to re-capping a vintage amplifier, but figured it was useful and self-contained enough to stand on…

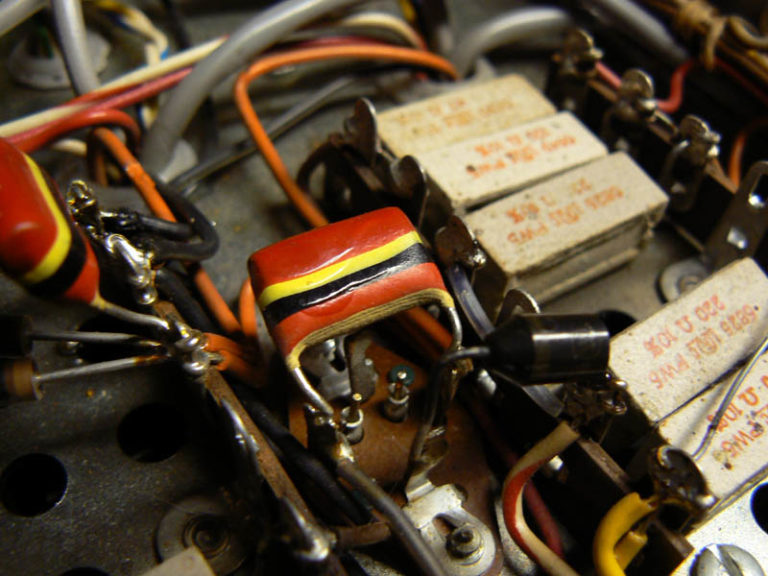

‘Audio’ Capacitors are bogus!

There are a number of boutique manufacturers (such as Jensen and the legendary Black Gate) that promise superior performance for audio applications. Some use exotic…

How to Pick Audio Capacitors

So, you’ve decided to repair/upgrade your vintage audio equipment by replacing the capacitors. When you go to Mouser or Digikey, however, you are presented with…