Such would be the successive phases of the image:it is the reflection of a profound reality;it masks and denatures a profound reality;it masks the absence…

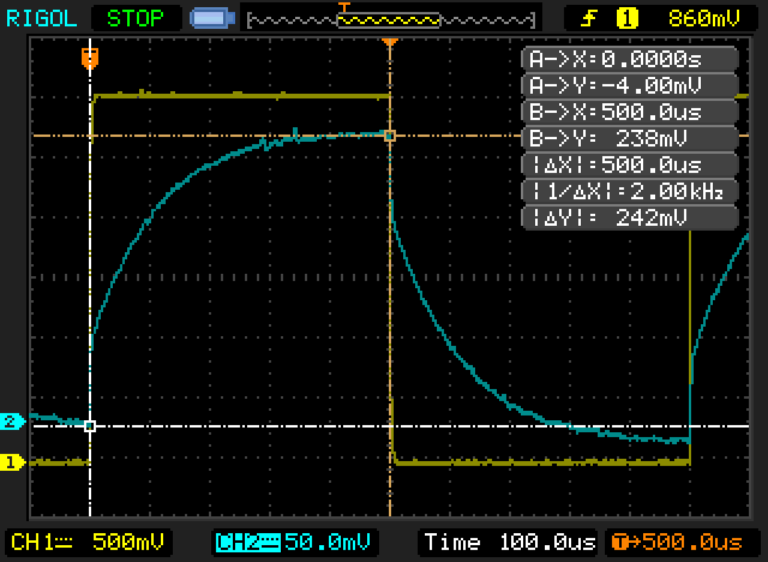

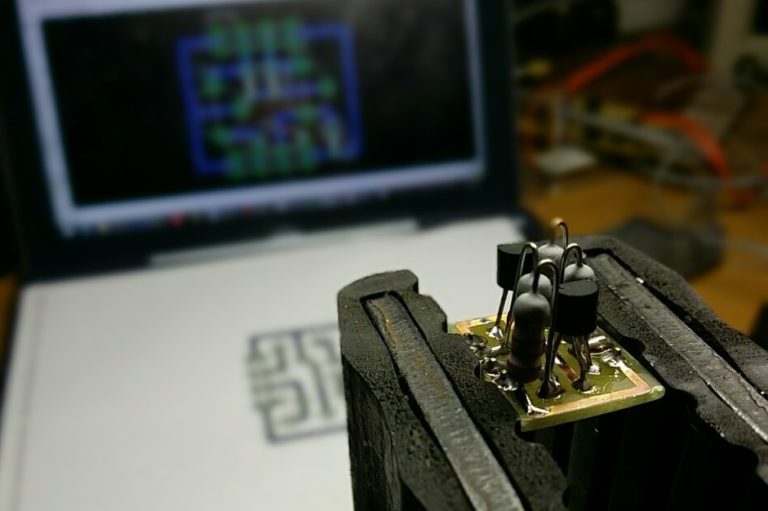

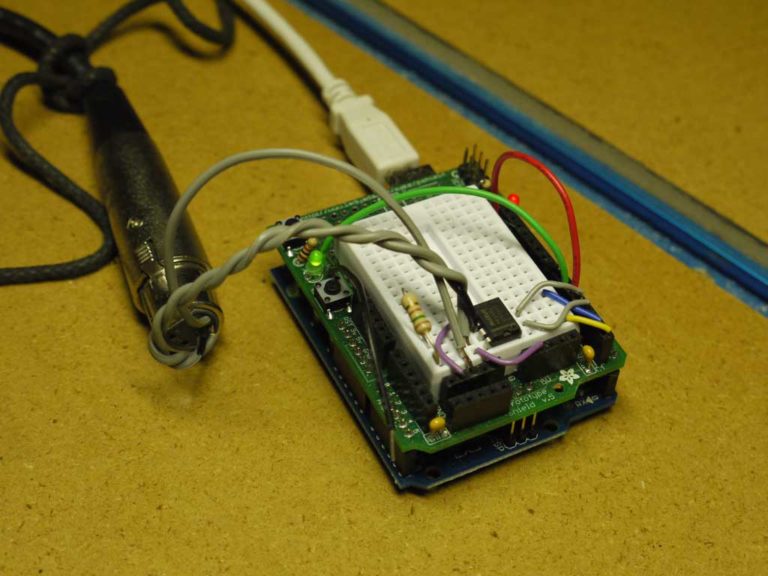

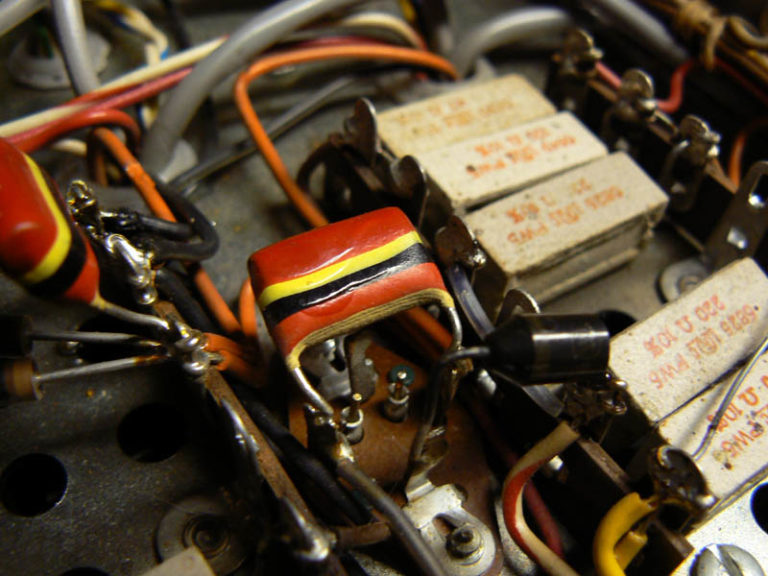

Capacitive sensing on Arduino – A better way

For a project I’m working on, I want some functionality to be triggered by touching a metal plate. Actually, I would ideally like the user…

Art from Disaster: Thoughts on the Beirut Port Explosion

We moved to Beirut in August of 2019. In October of that year, the largest anti-government protests in decades kicked off. What started as a…

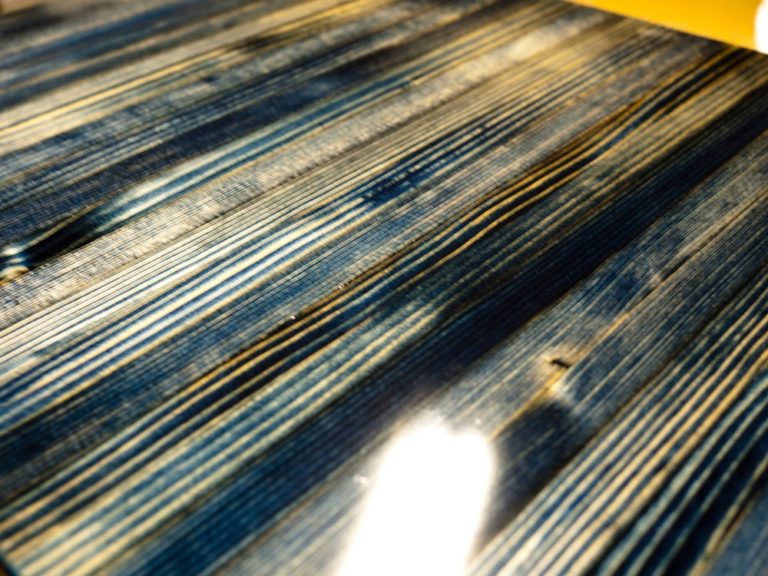

Galaxy Table

I made this table from mostly scavenged objects from the streets of San Francisco. The outer frame is old-growth douglas fir, made from some doors…

Upcycling an Ikea Desklamp

I’m quite happy with this ‘new’ desk lamp I made for myself, upcycled from an ugly-ass ikea desk lamp that I’ve had since forever: The…

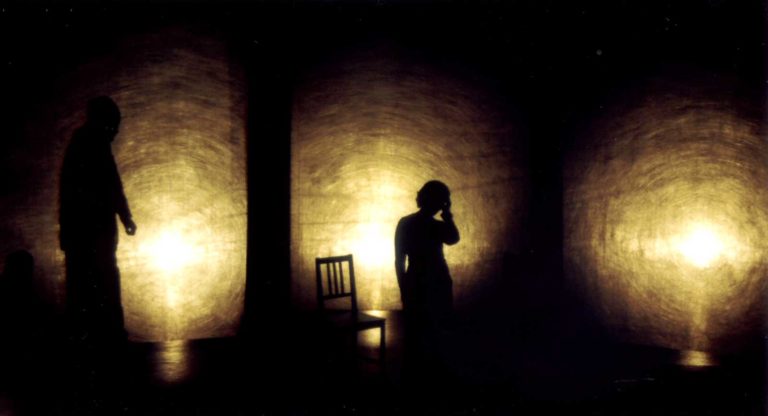

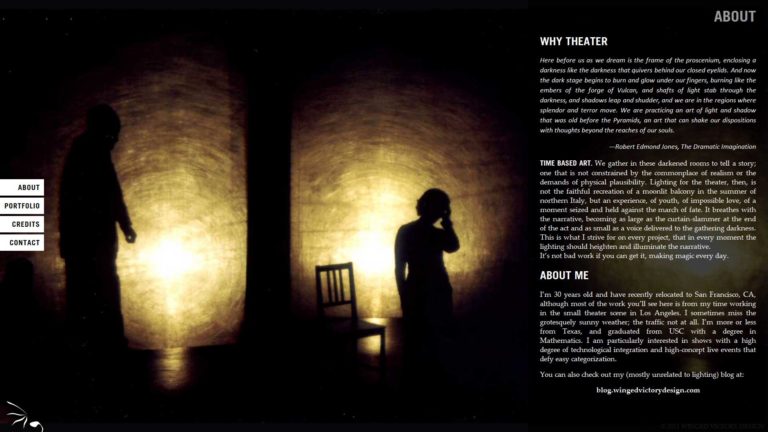

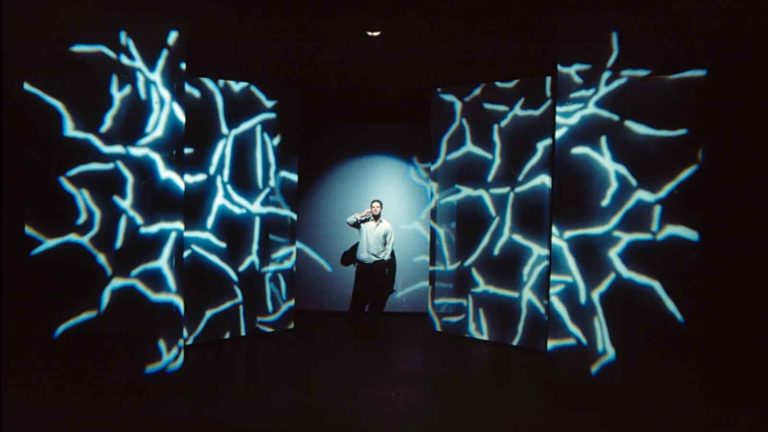

Lighting Design for Theater

This work is from my early career, when I was fresh out of school and working as a theatrical lighting designer in Los Angeles. I…

A New(er) Workbench

One of the very first posts on this blog was about the first workbench I built (here). In the ensuing ten (!) years, I’ve used…

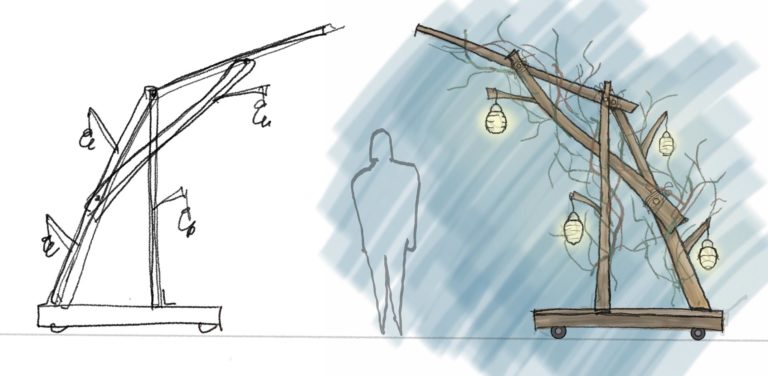

Bird Architecture

Delphine recently directed her students in an adaptation of Aristophanes’ The Birds, and asked for some help with the scenery. In the play, birds and…

Gallery: Kodak No. 1a

This Kodak no. 1a came to me from my great-grandfather. The date of the patents inside dates it from about 1908, although Kodak made this…

Aaah I finally finished this bench

One day THREE YEARS AGO, I found a whole pile of wooden doors on the street. They were nice solid things, mostly douglas fir and…

Wooden-bodied jointer plane tune-up and use

I bought this jointer plane at a flea market in the Czech Republic. I think I paid around $15. I wasn’t sure if it would…

2018 in Photos

Here’s the year in bread:

#melange

No particular organizing theme for this gallery, just a 🍕 of life:

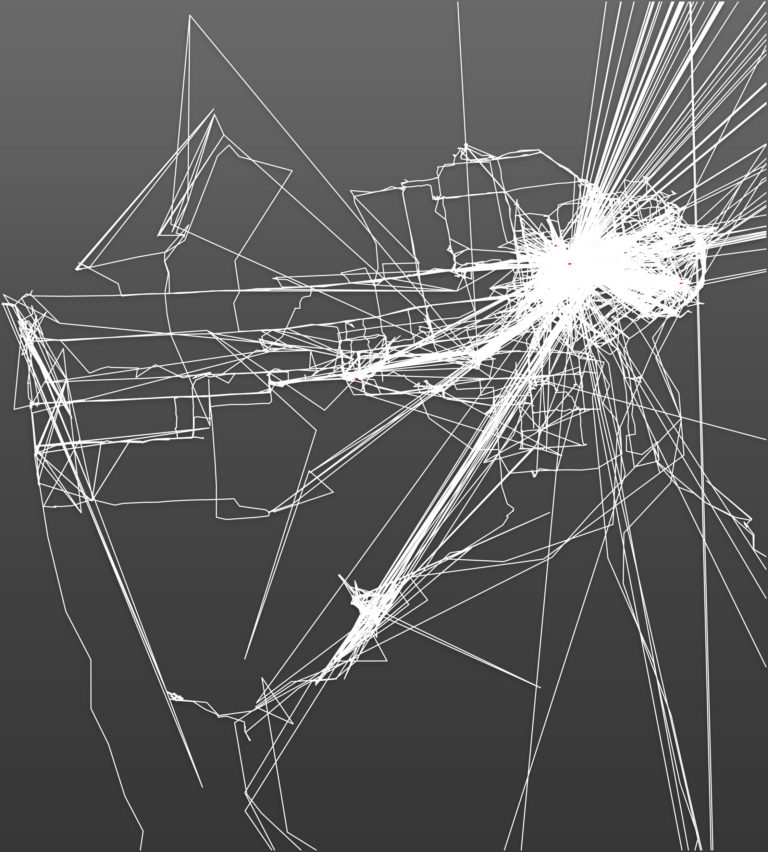

Mapping Your Life

As you may know, your smartphone can track your location over time. I’ve had location tracking enabled continuously since 2012, because I think it’s…

The Chilopod

So I went to Burning Man for the first time. It was strange and wonderful and difficult and beautiful, often at the same time. I…

Gallery: Joshua Tree National Park

We went backpacking in Joshua Tree National Park over memorial day weekend. The weather was perfect, the last weekend of the year where you could…

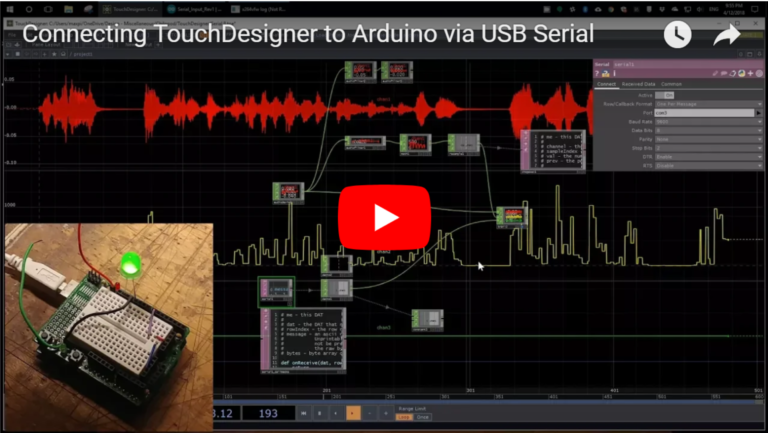

I made a thing with TouchDesigner

TouchDesigner is a visual programming interface to make interactive video art, I guess? I’ve been doing some work with it lately, for a larger-scale project…

Redwood Planter Boxes, the Sequel

We had a lot of pots taking up floor space on the deck in the new place, so I built these redwood planter boxes for…

Summer, France

Photos from our visit to Saint-Malo, France with my family and some time in Paris with friends, ending at Delphine’s parents’ house in the north…

Let’s combine a cheap wireless doorbell with a century-old phone

We recently (ish) moved into a new place, a big old victorian in the Haight. There’s funky historical There was no doorbell for our unit,…

Parklet Design Assignment

Another project I did for my Arch 134 class. The assignment was: Design a parklet! Concept I started with the Tenderloin neighborhood in San Francisco where…

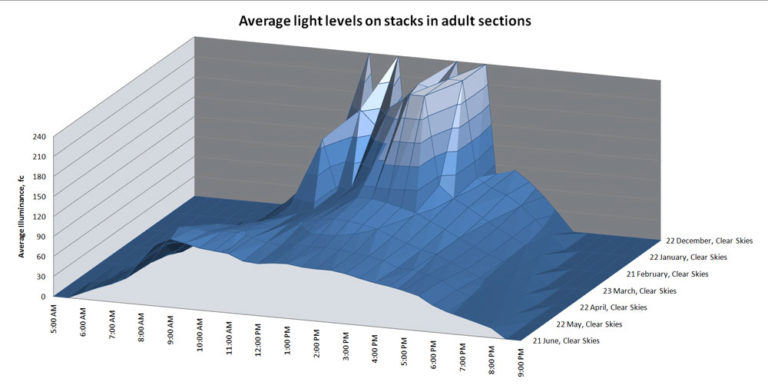

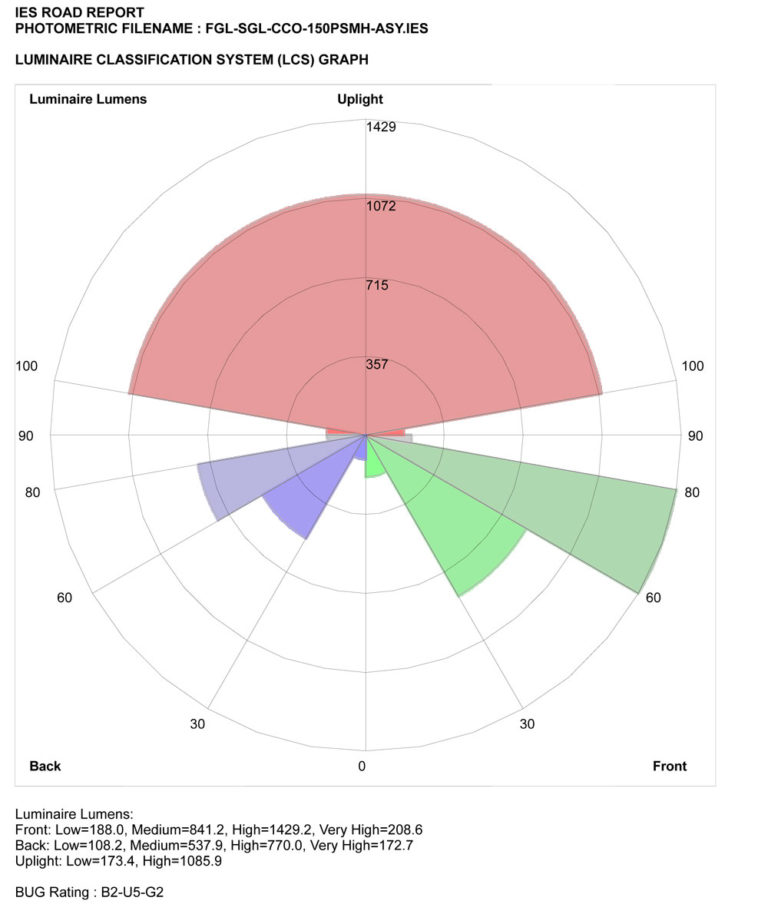

West Berkeley Public Library: A Case Study in Zero-Net Energy Lighting Design

I wrote this article on lighting design strategies for zero-net buildings for the Journal of Green Building. As a case study, I used my West…

Rolleicord Shutter Repair

Thanks for nothing, Vivian Maier: So this starts with a trip to Chicago. While we were there, we visited the Chicago History Museum and it…

Winding Sticks! So Useful!

I’ve been doing some woodworking stuff, and I’ve been finding that the thing I’m really enjoying is making the tools I need. Thus, the…

Poetics in Architecture Collage Assignment

So I’ve been taking a class at CCSF, History and Theory of Modern Architecture. I didn’t major in architecture, and actually I’ve been kind of making this…

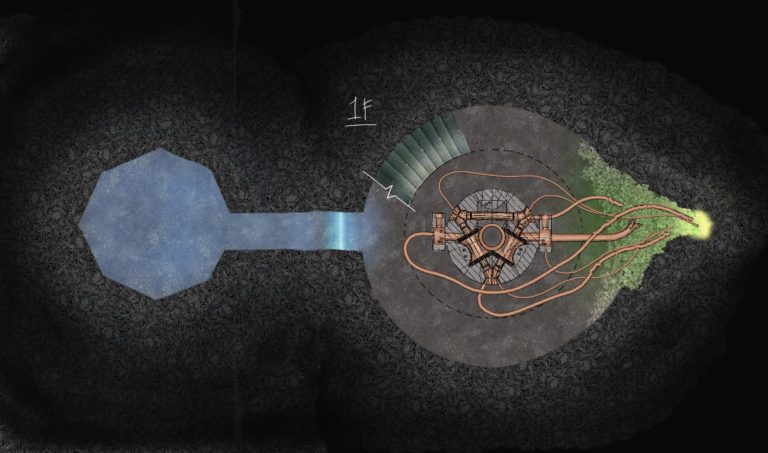

Artwork for Craggin’s Lament, a Dungeons and Dragons campaign

Some of you may know I run a Sunday night Dungeons and Dragons campaign (specifically Pathfinder, with Roll20 for our virtual table top). If that’s…

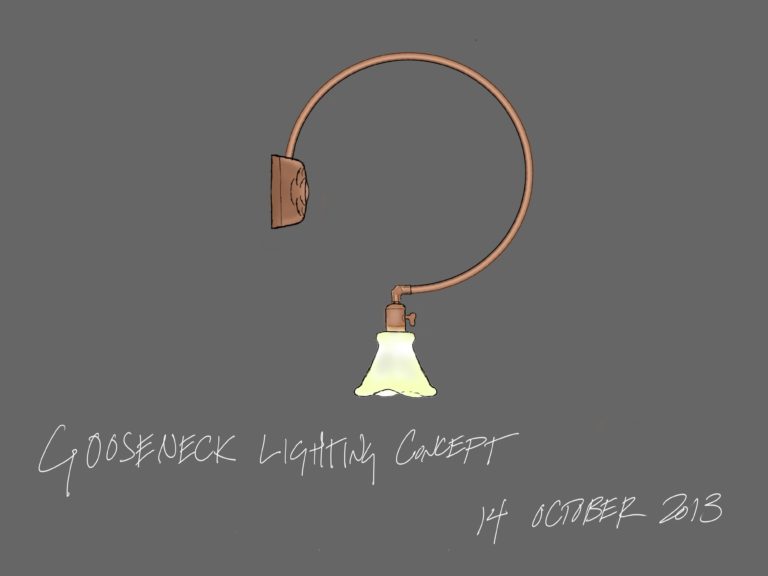

My Conduit Bending Machine

Oh hey there. As part of the theater show I’m working on I’ve been making these industrial gooseneck type things for the bar lighting. As…

In Appreciation: J. Robert Anderson

Regular service will resume shortly: I want to say a few words about my Uncle Bob, who passed away a few weeks ago. At the…

LEED v4 for the Lighting Designer

The next version of LEED is coming… Slowly. What was originally slated to be LEED 2012 has been approved by membership and will be rolled…

Backpacking Lassen Volcanic National Park

Lassen is a gem. The Southwest part of the park was still mostly under snow when I was there in the second week of June,…

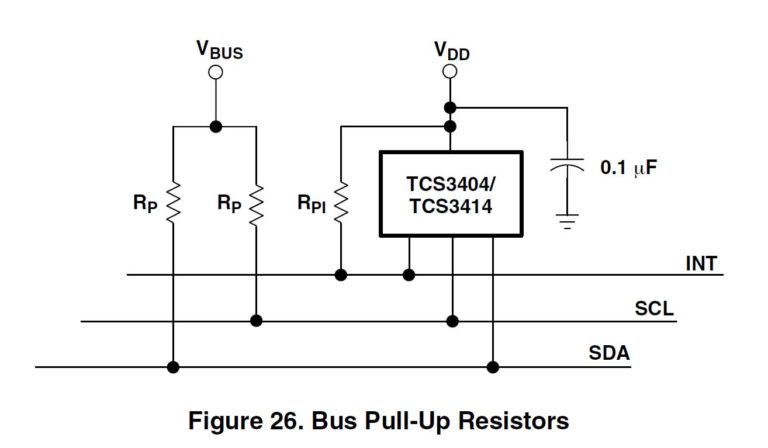

Interfacing the Arduino to the Taos TCS3414 via I2C, continued

November, so soon! I kind of had to put this one down for awhile and work on things that were not laptop-centric, I just was…

Pinhole Camera – Yosemite

Travel+Photography: I took the pinhole camera I made backpacking in Yosemite National Park./ And some back in San Francisco: Coming whenever I get around to…

Interfacing the Arduino to the Taos TCS3414 via I2C

Well, this was a productive night: I’ve been working with the Taos TCS3414, which is a light and RGB color sensor. It’s a tiny little…

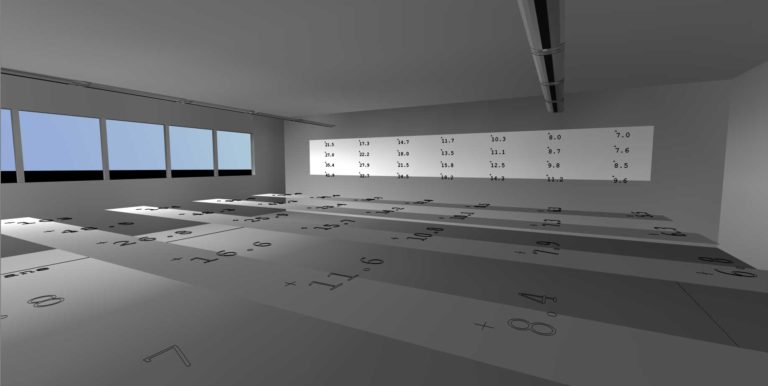

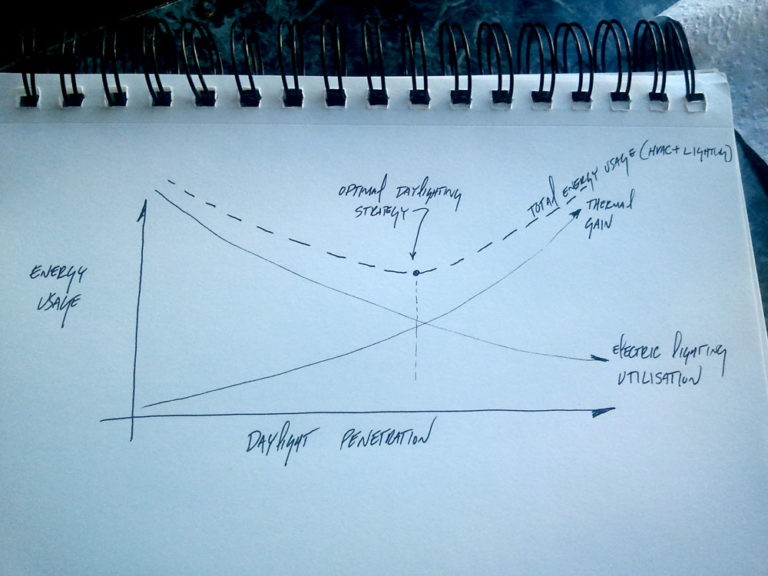

An Overview of Daylighting Metrics, with Examples

Why Daylighting: As an (electrical) lighting designer, daylighting is exciting to me for a lot of reasons. There are energy conservation reasons, of course–40% of…

True West with Boxcar Theater Company

Here is something you can do on Friday: Now playing at the Hyde Street Studios with Boxcar Theater company, True West by Sam Shepard. This…

thecontinentalstar.com, a Blog for my Dad

So Many Thingssssss: I’ve been so busy working on projects that I haven’t had time to write about them! Here is some of what I’ve…

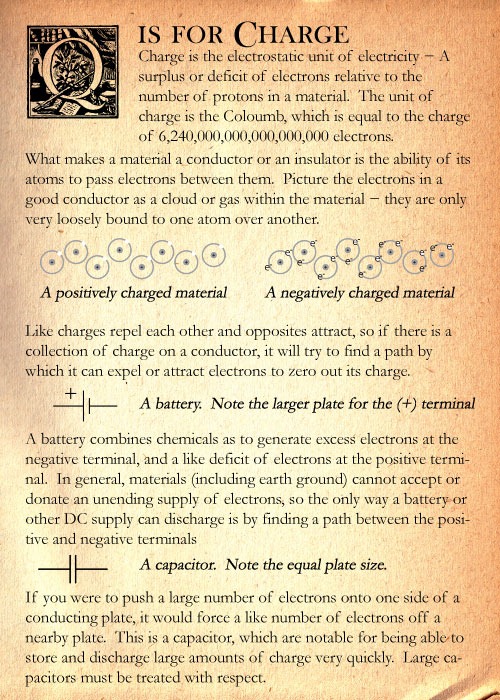

Electricity Quick Reference Cards

These are some quick reference guides I made for my dad, for Christmas. I am posting it now because June is the next month after…

Incorporating Daylighting in Lighting Design: Part I

Image above: South exposure glazing at 3pm, noon, and 9am. Prologue: I have been wanting for to better educate myself on daylighting design and analysis,…

West Berkeley Library, a Zero-Net Facility

Update: This article was written early in the design process and the library underwent considerable development after it was written. I’ve since written a case…

My Nixie Clock Build

It’s finally done, jesus. A few years ago, I bought some electronics components from a former Eastern Bloc country. Nixie tubes are apparently still…

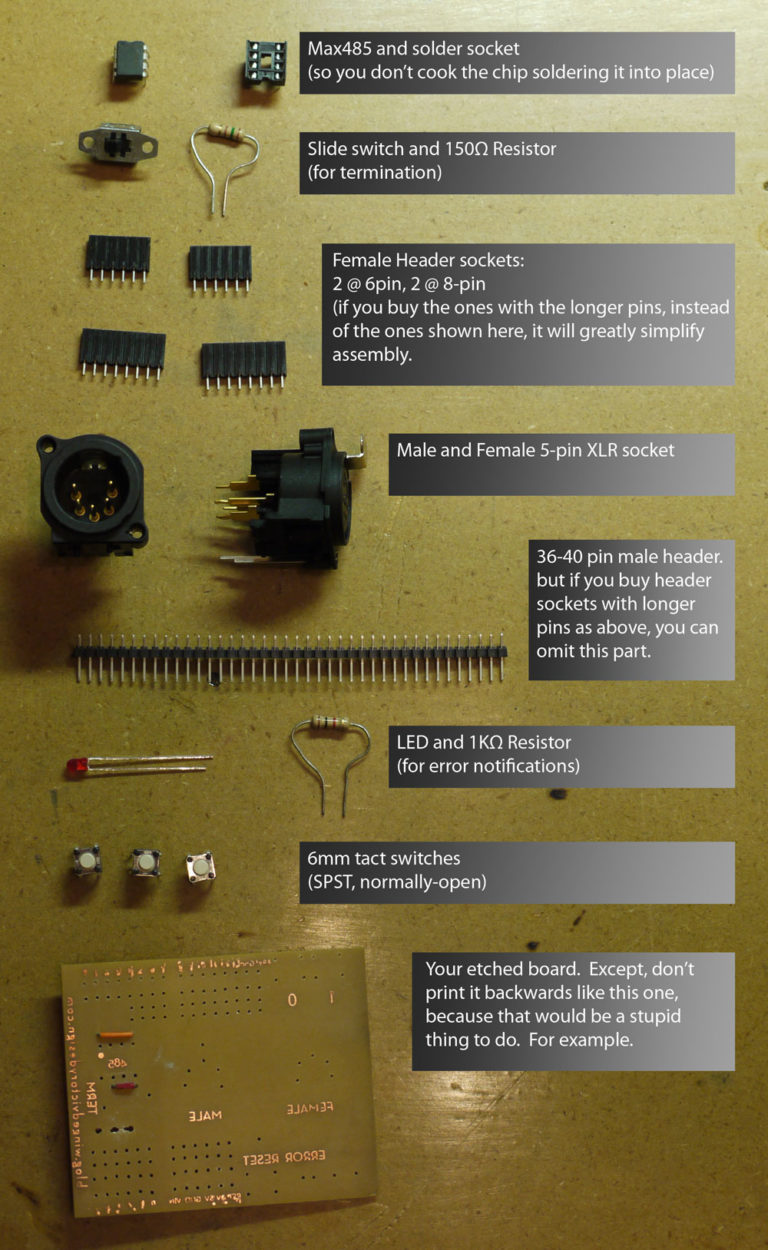

Rev15 of the Arduino DMX Reception Software Released

New in this version: Tested and working with IDE version 0021. I have not tested it with the new Arduino Uno hardware, but can’t think…

IES BUG Ratings

Cutoff is dead. Long live Cutoff. Most lighting designers are somewhat familiar with the Cutoff classification system for fixtures. It’s a measure of how well…

Look what I found!

I was walking home and these were just laying out on the street. I think they were slats in a bed, maybe? Anyway, they’re nice…

Copper Plating onto Zinc

You win some, You lose some. This is actually a post about a failure to achieve what I was trying to do, but it’s an…

A New Workbench

Story Time. So, in Los Angeles I lived in this comically tiny studio apartment. There, I did all my projects on this 3′ x 3′…

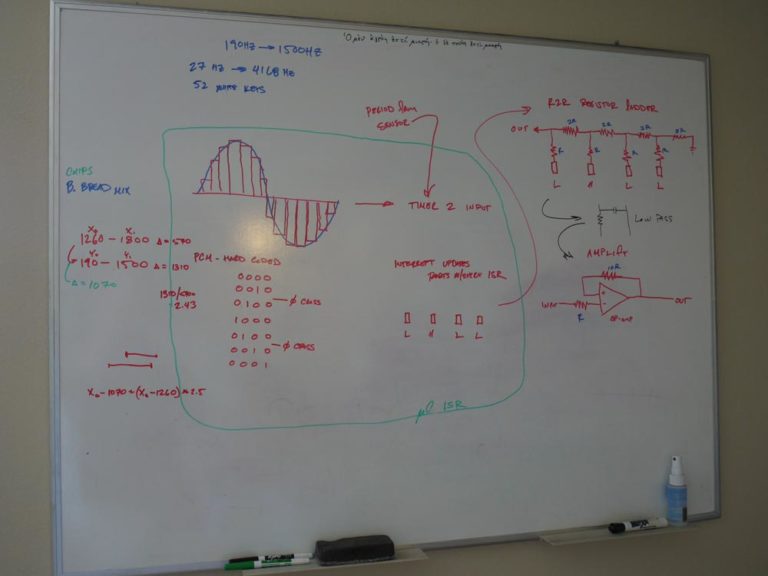

Generate Real-time Audio on the Arduino using Pulse Code Modulation

So. There are a bewildering variety of options for generating sound via the Arduino, but I’m trying to make a real-time synthesizer, with the following…

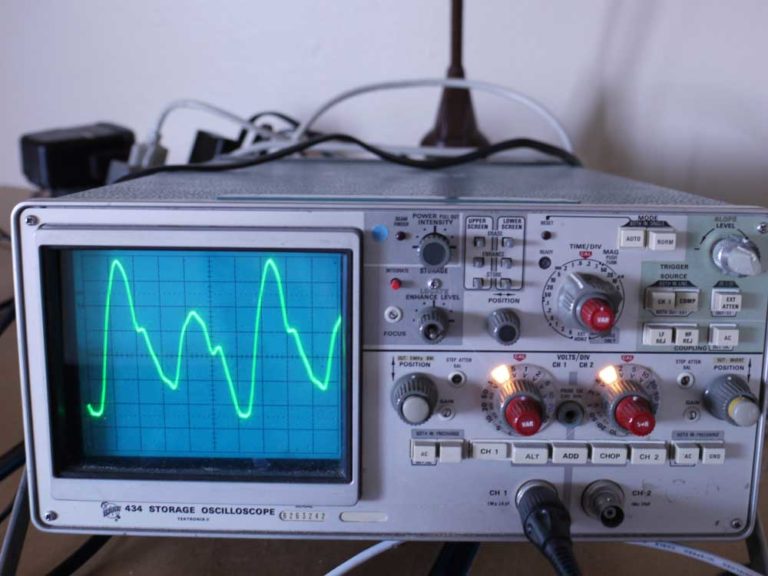

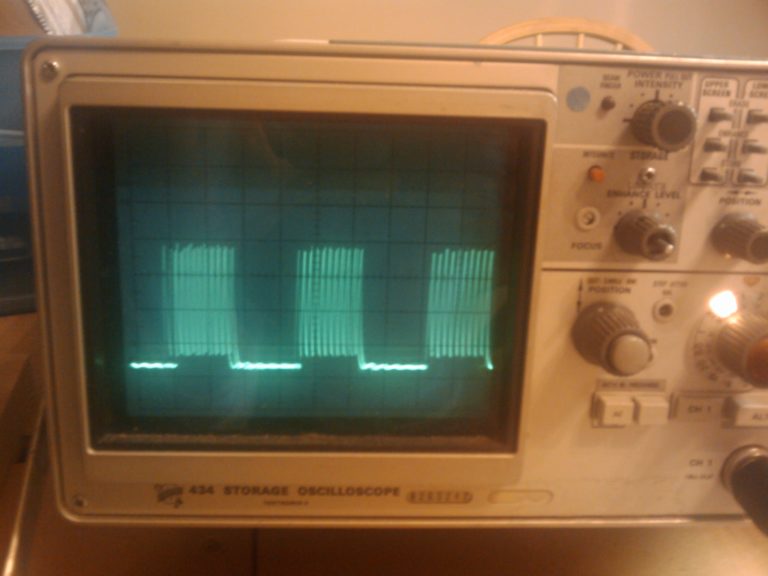

Arduino Theremin/Synthesizer Update

An Update: I’ve made considerable progress in improving the quality of the audio output. In the prior post, I was generating a square wave with…

Arduino audio output from a capacitive input

Lookee Lookee What I Did Today: So my sister is currently pursuing a PHD in music (theory) at the University of Chicago, and for her…

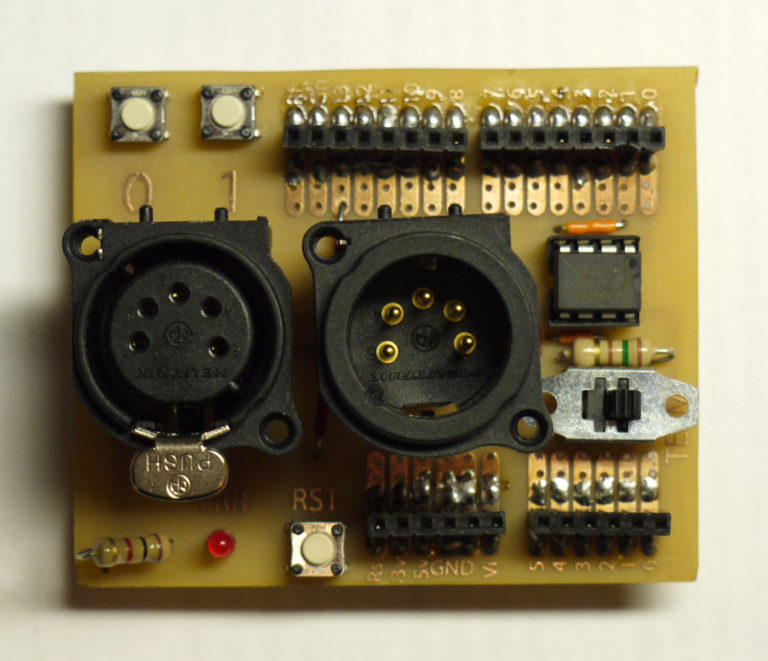

Rev12 of the Arduino DMX Reception Software Released

Update: This is no longer the latest version of the software. Find that here. New in this Version: In-the-field addressing via two tact switches (works…

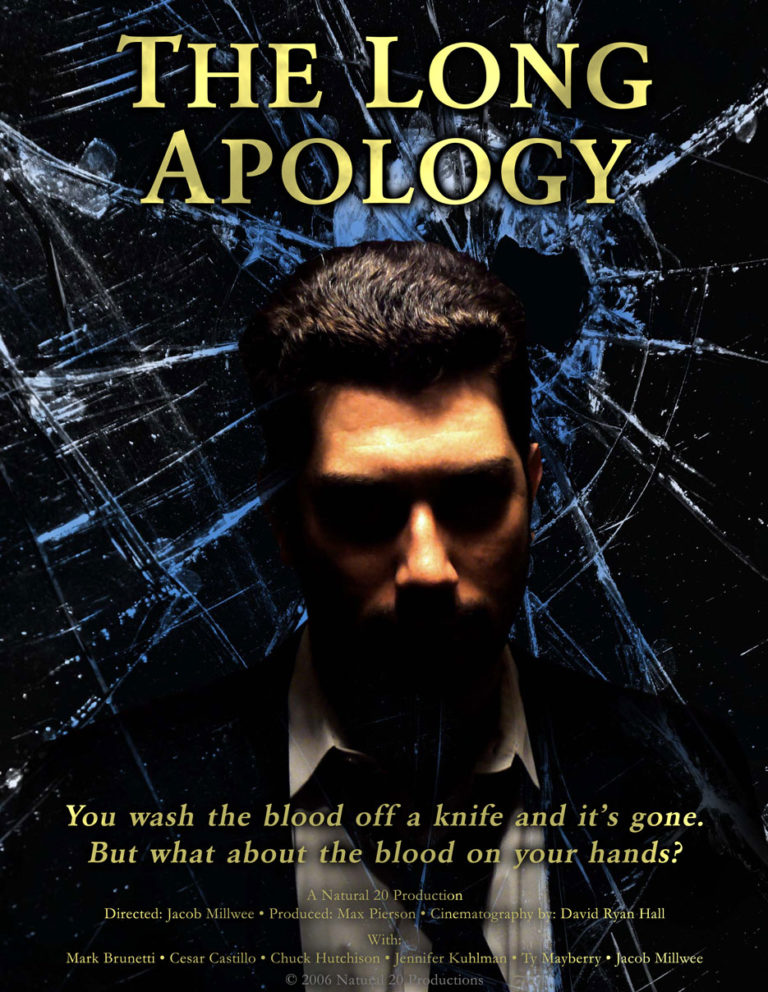

A DVD jacket for The Long Apology

A Little While Ago, I produced a film with some friends of mine called The Long Apology. We’re nearing the end of post-production, and it’s…

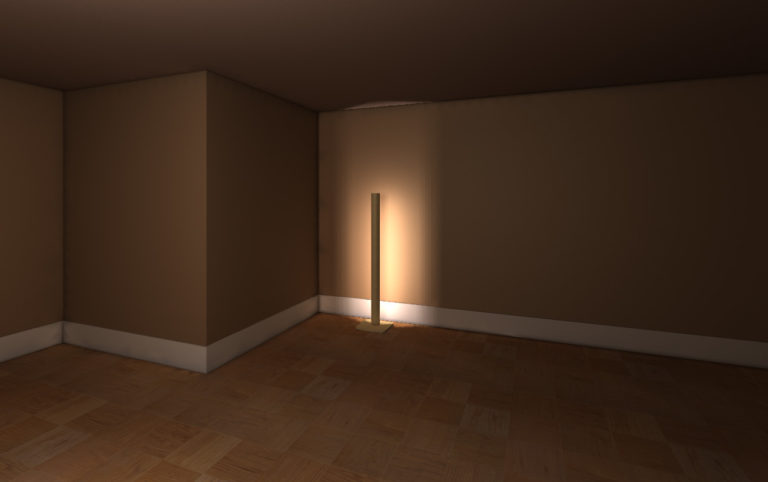

A New Floor Lamp, Part III

Or, dispensing with the floor part:

A New Floor Lamp, Part II

Or, I Could Do Something Like This:

A New Floor Lamp

There’s a Corner of my Apartment that is a Problem. See, my windows face north, so even on sunny days, which are rarer than unicorns…

Receive DMX-512 with an Arduino

Prologue: For Christmas, I received an Arduino. If you’re not familiar with them, they’re like a little computer with a lot of pins to which…

Power Rectification Explained

I wrote this up as part of my guide to re-capping a vintage amplifier, but figured it was useful and self-contained enough to stand on…

‘Audio’ Capacitors are bogus!

There are a number of boutique manufacturers (such as Jensen and the legendary Black Gate) that promise superior performance for audio applications. Some use exotic…

How to Pick Audio Capacitors

So, you’ve decided to repair/upgrade your vintage audio equipment by replacing the capacitors. When you go to Mouser or Digikey, however, you are presented with…

Arcadia

A lighting design for Tom Stoppard’s masterpiece

Wilhelm Reich in Hell

Note: This content originally appeared on my theatrical lighting design portfolio site, www.wingedvictorydesign.com. I decommissioned that site to reduce the number of websites that I…

Mr. and Mrs. B

A lighting design for an interconnected pair of plays about a marriage, and what comes after